Hyundai Ioniq (AE): Lubrication System / Oil Pressure Switch. Repair procedures

| Removal and Installation |

| 1. | Disconnect the battery negative terminal. |

| 2. | Remove the engine room under cover. (Refer to Engine and Transaxle Assembly - "Engine Room Under Cover") |

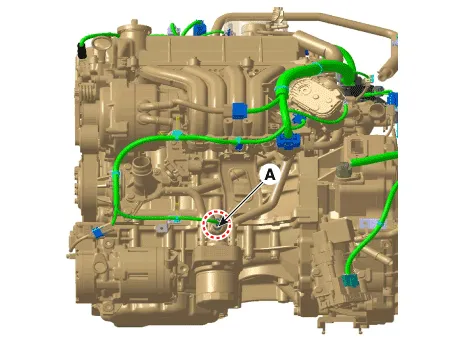

| 3. | Disconnect the oil pressure switch connector (A).

|

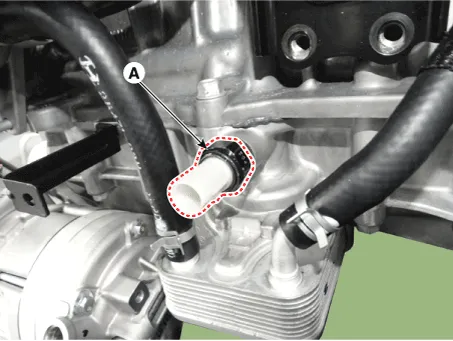

| 4. | Remove the oil pressure switch (A).

|

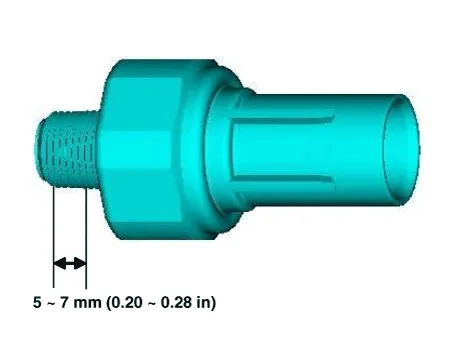

| 5. | Install in the reverse order of removal.

|

| Inspection |

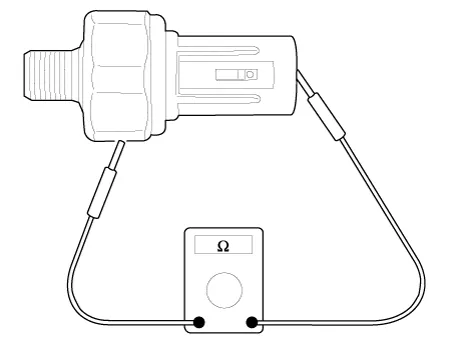

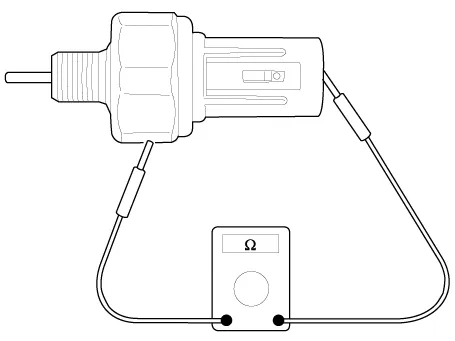

| 1. | Check the continuity between the terminal and the body with an ohmmeter. If there is no continuity, replace the oil pressure switch.

|

| 2. | Check the continuity between the terminal and the body when the fine wire is pushed. If there is continuity even when the fine wire is pushed, replace the switch. |

| 3. | If there is no continuity when a 50 kPa (0.50 kgf/cm², 7.25 psi) is applied through the oil hole, the switch is operaing properly. Check for air leakage. If air leaks, the diaphragm is broken. Replace it.

|

Removal and installation1.Remove the timing chain cover.(Refer to Timing System - "Timing Chain Cover")2.Remove the oil pump cover (A). Tightening torque : Screws :5.

Components1. Oil pan2. Oil screen3. Gasket4. Drain plug5. Drain plug gasket

Other information:

Hyundai Ioniq (AE) 2017-2022 Service & Repair Manual: Heater Unit. Repair procedures

Replacement When prying with a flat-tip screwdriver or use a prying trim tool, wrap it with protective tape, and apply protective tape around the related parts, to prevent damage.1.Disconnect the negative (-) battery terminal.2.Recover the refrigerant with a recovery / recycling / charging station.

Hyundai Ioniq (AE) 2017-2022 Service & Repair Manual: Rear Corner Radar Unit. Repair procedures

Removal1.Disconnect the negative (-) battery terminal.2.Remove the rear bumper.(Refer to Body - "Rear Bumper")3.Remove the rear corner radar unit (A) after loosening the mounting nuts. • Take care not to separate the bracket from rear bumper when removing the rear corner radar sensor.

Categories

- Manuals Home

- Hyundai Ioniq Owners Manual

- Hyundai Ioniq Service Manual

- General Information

- How to Connect Portable Charger (ICCB: In-Cable Control Box)

- Repair procedures

- New on site

- Most important about car