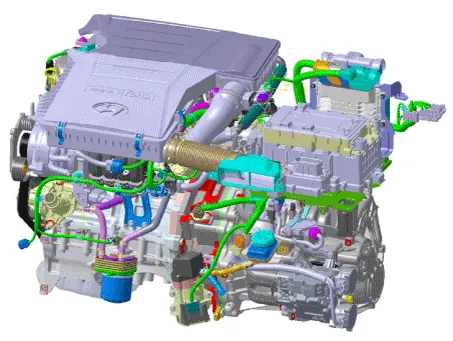

Hyundai Ioniq (AE): Cylinder Head Assembly / Cylinder Head. Repair procedures

Hyundai Ioniq (AE) 2017-2022 Service & Repair Manual / Engine Mechanical System / Cylinder Head Assembly / Cylinder Head. Repair procedures

| Removal |

Engine removal is not required for this procedure.

|

|

|

| 1. | Shut off the High Voltage circuit. (Refer to General Information - "High Voltage Shutoff Procedure") |

| 2. | Disconnect the battery negative terminal. |

| 3. | Remove the air cleaner assembly. (Refer to Intake and Exhaust System - "Air Cleaner") |

| 4. | Remove the RH front wheel. (Refer to Suspension System - "Wheel") |

| 5. | Remove the engine room under cover. (Refer to Engine and Transaxle Assembly - "Engine Room Under Cover") |

| 6. | Loosen the drain plug, and drain the engine coolant. Remove the reservoir cap to help drain the coolant faster. (Refer to Cooling System - "Coolant") |

| 7. | Loosen the drain plug, and drain the inverter coolant. Remove the reservoir cap to help drain the coolant faster. (Refer to Hybrid Motor System - "Coolant") |

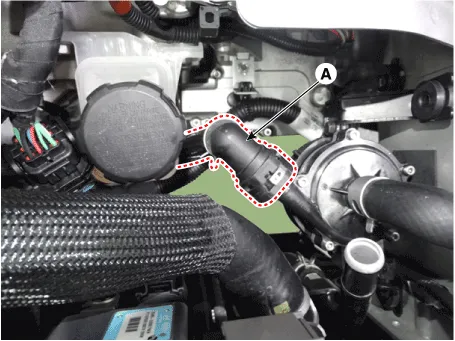

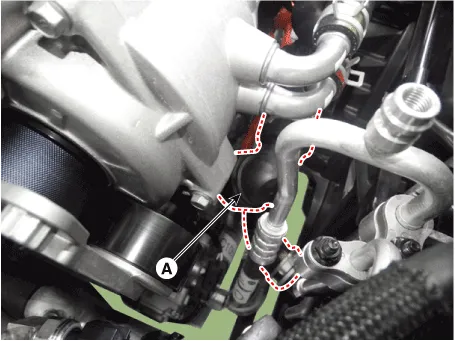

| 8. | Disconnect the electric water pump (EWP) coolant hose (A).

|

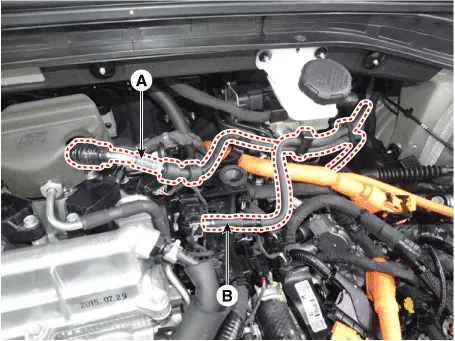

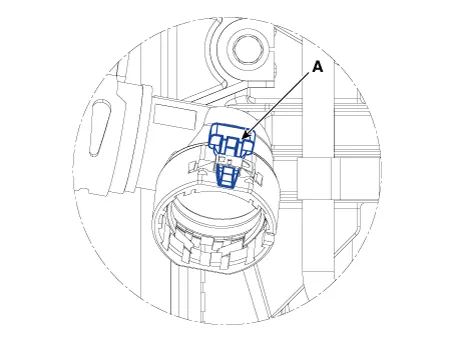

| 9. | Disconnect the fuel hose (A) and the purge control solenoid valve (PCSV) hose (B).

|

| 10. | Disconnect the wiring connectors and harness clamps and remove the connector brackets around the cylinder head.

|

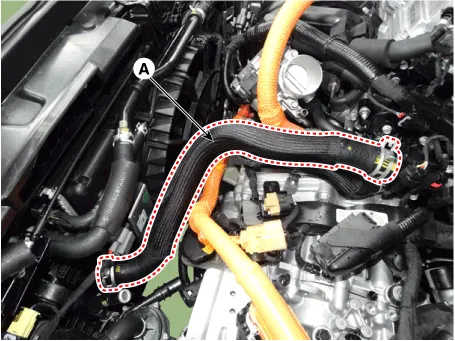

| 11. | Disconnect the heater hoses (A).

|

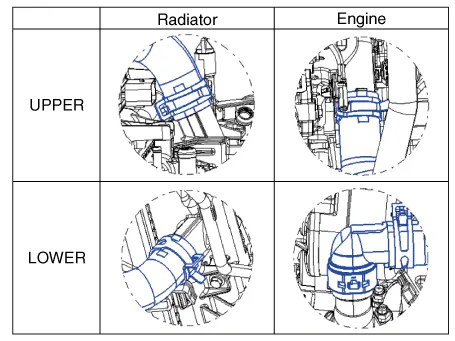

| 12. | Disconnect the radiator upper hose (A).

|

| 13. | Disconnect the radiator lower hose (A).

|

| 14. | Remove the water temperature control assembly. (Refer to Cooling System - "Water Temperature Control Assembly") |

| 15. | Remove the cylinder head cover. (Refer to Cylinder Head Assembly - "Cylinder Head Cover") |

| 16. | Remove the intake manifold. (Refer to Intake and Exhaust System - "Intake Manifold") |

| 17. | Remove the exhaust manifold. (Refer to Intake and Exhaust System - "Exhaust Manifold") |

| 18. | Remove the timing chain. (Refer to Timing System - "Timing Chain") |

| 19. | Remove the heater pipe. (Refer to Cooling System - "Water Temperature Control Assembly") |

| 20. | Remove the electric EGR (EEGR) control valve. (Refer to Engine Control / Fuel System - "Electric EGR Control Valve (EEGR)") |

| 21. | Remove the CVVT & camshaft. (Refer to Cylinder Head Assembly - "CVVT & Camshaft") |

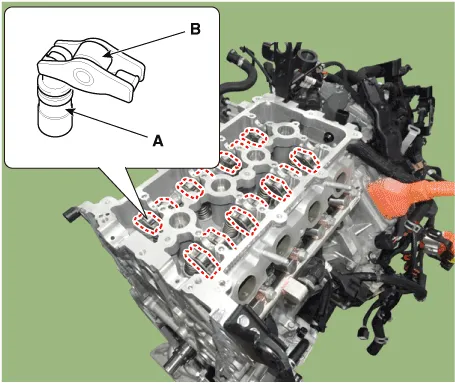

| 22. | Remove the hydraulic lash adjuster (HLA) (A) and the swing arm (B).

|

| 23. | Remove the spark plugs. (Refer to Engine Electrical System - "Spark Plug") |

| 24. | Remove the cylinder head.

|

| Disassembly |

|

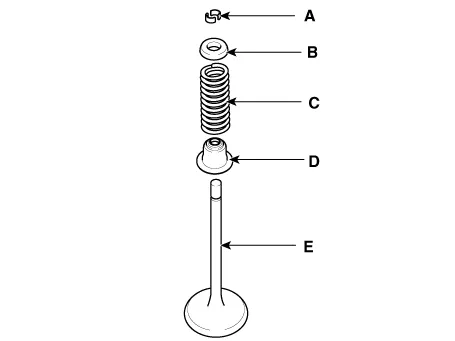

| 1. | Remove the valves.

|

| Inspection |

Cylinder Head

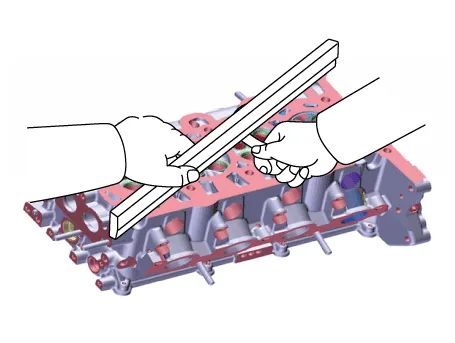

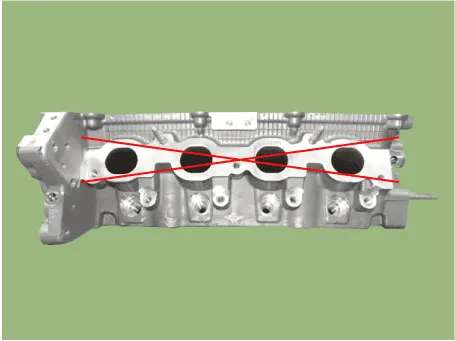

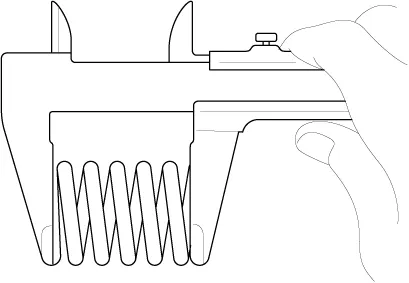

| 1. | Inspect for flatness. Using a precision straight edge and feeler gauge, measure the surface contacting cylinder block and the manifolds for warpage.

|

| 2. | Inspect for cracks. Check the combustion chamber, intake ports, exhaust ports and cylinder block surface for cracks. If cracked, replace the cylinder head. |

Valve and Valve Spring

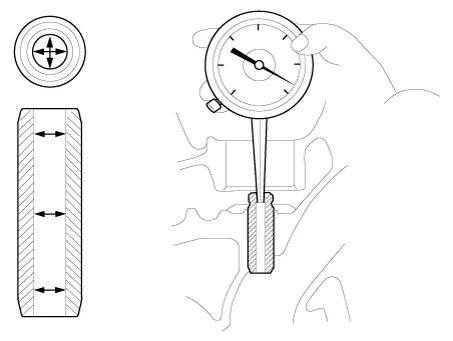

| 1. | Inspect valve stems and valve guides.

|

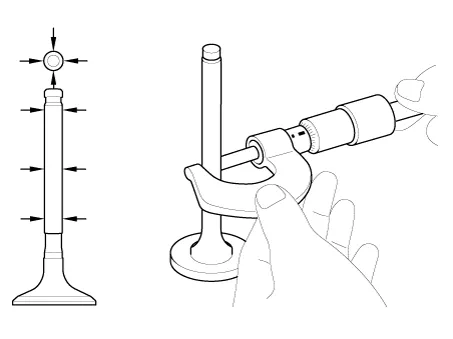

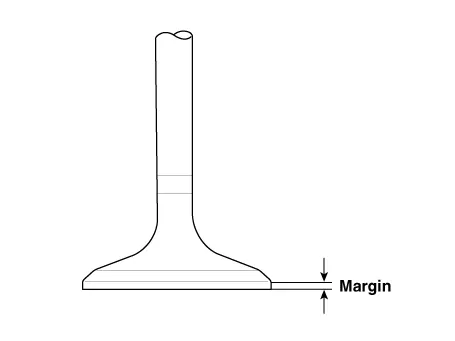

| 2. | Inspect valves.

|

| 3. | Inspect valve seats.

|

| 4. | Inspect valve springs.

|

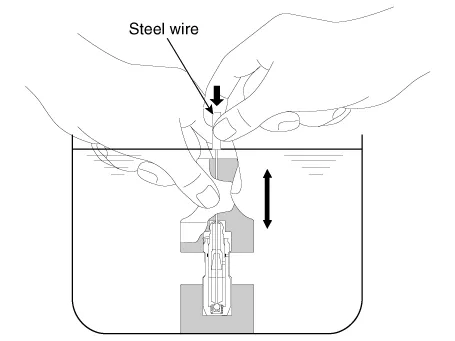

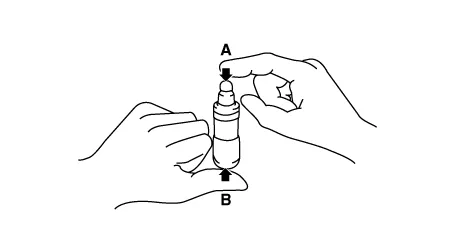

HLA (Hydraulic Lash Adjuster)

With the HLA filled with engine oil, hold A and press B by hand. If B moves, replace the HLA.

| Problem | Possible cause | Action | |||||

| 1. Temporary noise when starting a cold engine | Normal | This noise will disappear after the oil in the engine reaches the normal pressure. | |||||

| 2. Continuous noise when the engine is started after parking more than 48 hours | Oil leakage of the high pressure chamber on the HLA, allowing air to get in | Noise will disappear within 15 minutes when engine runs at 2000-3000 rpm. If it doesn’t disappear, refer to step 7 below. | |||||

| 3. Continuous noise when the engine is first started after rebuilding cylinder head | Insufficient oil in cylinder head oil gallery | ||||||

| 4. Continuous noise when the engine is started after excessively cranking the engine by the starter motor or band |

| ||||||

| 5. Continuous noise when the engine is running after changing the HLA |

| ||||||

| 6. Continuous noise during idle after high engine speed | Engine oil level too high or too low |

| |||||

| Excessive amount of air in the oil at high engine speed | Check oil supply system. | ||||||

| Deteriorated oil | Check oil quality. If deteriorated, replace with specified type. | ||||||

| 7. Noise continues for more than 15 minutes | Low oil pressure | Check oil pressure and oil supply system of each part of engine. | |||||

| Faulty HLA | Remove the cylinder head cover and press HLA down by hand. If it moves, replace the HLA. |

| Reassembly |

|

| 1. | Install the valves.

|

| Installation |

|

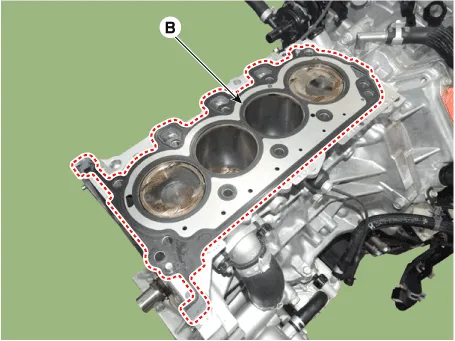

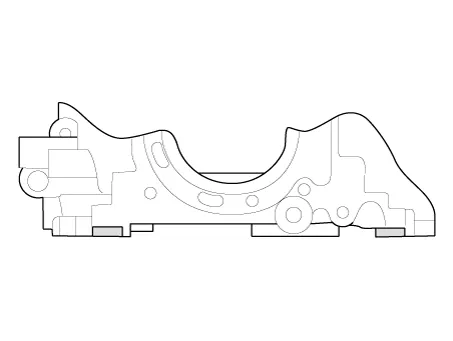

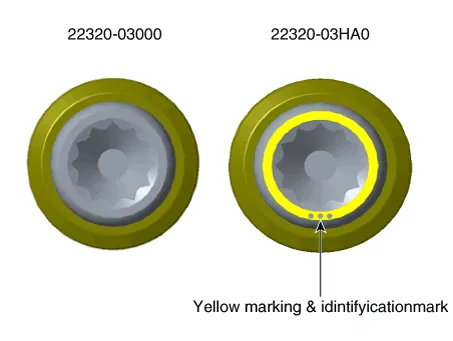

| 1. | Install the cylinder head gasket.

|

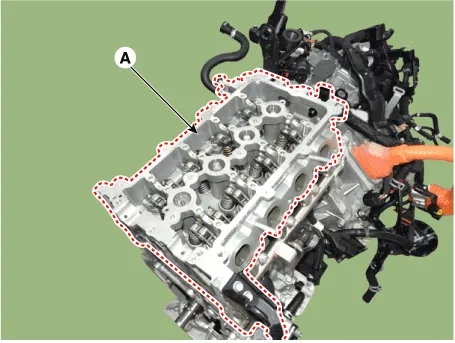

| 2. | Place the cylinder head (A) carefully to protect damage to the head gasket during installation.

|

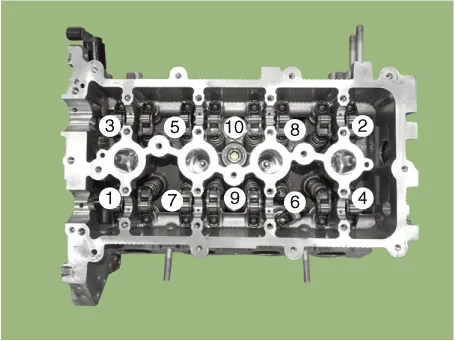

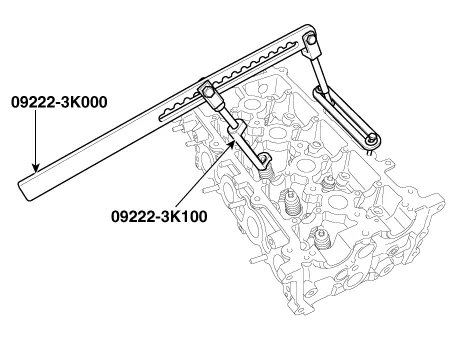

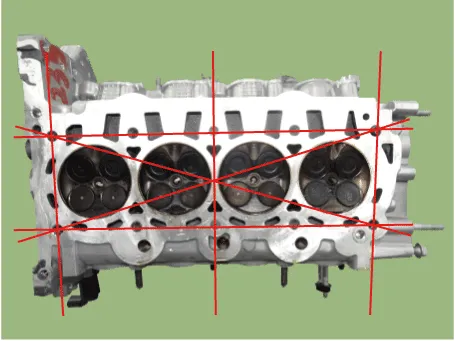

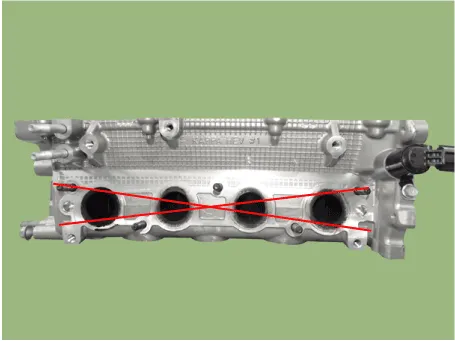

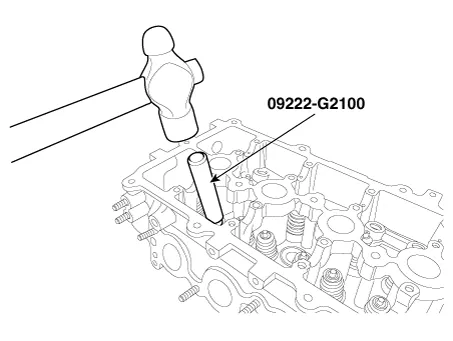

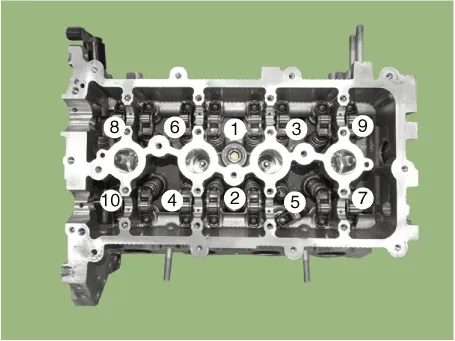

| 3. | Install the cylinder head bolts with washers. Using SST (09221-4A000), install and tighten the 10 cylinder head bolts, in several passes, in the sequence as shown.

|

| 4. | Install the spark plugs. (Refer to Engine Electrical System - "Spark Plug") |

| 5. | Install the hydraulic lash adjuster (HLA) (A) and the swing arm (B).

|

| 6. | Install the other parts reverse order of removal. |

| 7. | Connect the High Voltage circuit. (Refer to General Information - "High Voltage Shutoff Procedure")

|

Components1. Cylinder head assembly2. Cylinder head gasket3. Retainer lock4. Retainer5. Valve spring6. Valve stem seal7. Valve8. Swing arm9. Hydraulic lash adjuster (HLA)

Other information:

Hyundai Ioniq (AE) 2017-2022 Service & Repair Manual: Front Radar Unit. Specifications

S

Hyundai Ioniq (AE) 2017-2022 Service & Repair Manual: Troubleshooting

Trouble Symptom ChartsTrouble Symptom 1Trouble Symptom 2 Trouble symptom Probable cause Remedy The set vehicle speed varies greatly upward or downward"Surging" (repeated alternating acceleration and deceleration) occurs after settingMalfunction of the vehicle speed se

Categories

- Manuals Home

- Hyundai Ioniq Owners Manual

- Hyundai Ioniq Service Manual

- Transmission Gear Oil. Repair procedures

- How to Connect Portable Charger (ICCB: In-Cable Control Box)

- Body (Interior and Exterior)

- New on site

- Most important about car

Copyright © 2026 www.hioniqae.com - 0.0147