Hyundai Ioniq (AE): DCT(Dual Clutch Transmission) System / Special service tools

| Special Service Tools |

|

Tool (Number and Name)

|

Illustration

|

Use

|

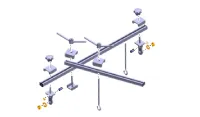

| 09200-3N000 Engine support fixture (Beam) |

| Removal and installation of the transaxle. Use this beam (SST No. : 09200-3N000) with the supporter (SST No. : 09200-2S000). ※Permit operating with 09200-38001. ※Refer to the engine support fixture assembly drawing below. |

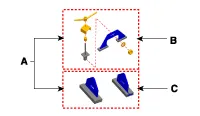

| A : 09200-2S000 B : 09200-2S100 C : 09200-2S200 Engine support fixture (Supporter) |

| Removal and installation of the transaxle. Use this beam (SST No. : 09200-38001/3N000) with the supporter (SST No. : 09200-2S000). ※Refer to the engine support fixture assembly drawing below. |

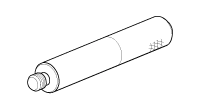

| 09430-C1190 Oil seal installer |

| Used for installing differential oil seal of both side Used with the handle (09231-H1100) |

| 09231-H1100 Handle |

| Used with the oil seal installer when installing oil seal |

| 09480-A3800 Inhibitor switch neutral fixed pin |

| When installing the manual control lever on the inhibitor switch, used to align the neutral position. |

| 09430-C1180 Dual clutch remover |

| Used for removing dual clutch assembly |

| 09430-2A240 Dual clutch Installer |

| Used for installing dual clutch assembly |

| 09430-G2100 Clutch actuator remover |

| Used for removing clutch actuator assembly |

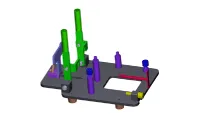

| 09430-F0100 Actuator fixing jig & Motor shaft reset tool |

| Used for adjusting clutch actuator Used with the Clutch actuator adjuster (09430-C1300) |

| 09430-C1300 Clutch abrasion compensation tool |

| Used for adjusting clutch actuator Used with the Clutch actuator adjustment jig (09430-F0100) |

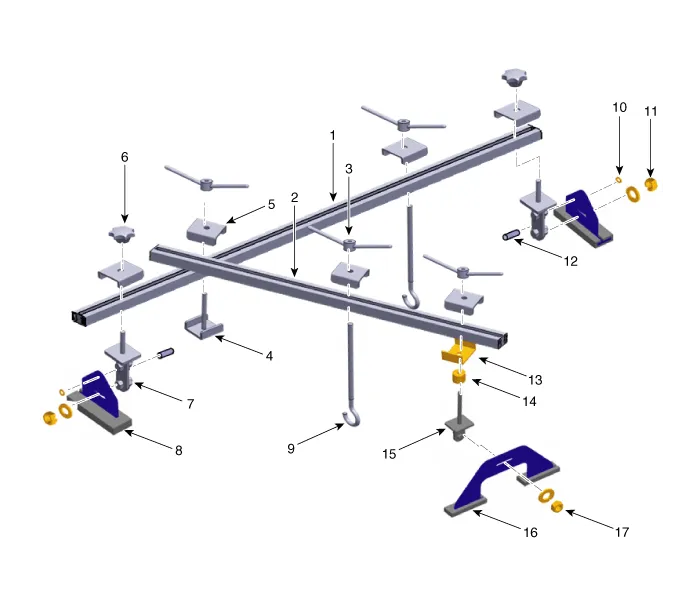

| 1. 09200-3N000(Main bar) 2. 09200-3N000(Sub bar) 3. 09200-3N000(Handle) 4. 09200-3N000(Stopper) 5. 09200-3N000(Stopper) 6. 09200-3N000(Knobe) 7. 09200-3N000(Adaptor) 8. 09200-2S000(Supporter) 9. 09200-3N000(Hanger) | 10. 09200-3N000(Clip) 11. 09200-3N000(Nut) 12. 09200-3N000(Pin) 13. 09200-2S000(Stopper) 14. 09200-2S000(Spacer) 15. 09200-2S000(Adaptor) 16. 09200-2S000(Supporter) 17. 09200-2S000(Nut) |

Specifications Transmission type D6KF1 Engine TypeKappa 1.6 GDITransmssion fluidQuantity1.6 - 1.7 L(0.

Troubleshooting Trouble symptom Probable cause Remedy Displayed the warning lamp "E"(Driving is only possible with 1/ R gear)Not performed DCT learningPerform the DCT manual learning procedure.

Other information:

Hyundai Ioniq (AE) 2017-2022 Service & Repair Manual: Repair procedures

Replacement1.Remove the battery (-) terminal.2.Remove the engine room under cover.(Refer to Engine Mechanical System - "Engine Room Under Cover")3.Remove the heater hose (A) and AEWP hose (B).4.Disconnect the lock pin to remove the heater hose pump connector (A).

Hyundai Ioniq (AE) 2017-2022 Service & Repair Manual: Cruise Control Switch. Repair procedures

Removal1.Disconnect the negative (-) battery terminal.2.Remove the steering wheel assembly.(Refer to Steering System - "Steering Wheel")3.Remove the steering back cover (A).4.Remove the steering remote control connector (A).5.Remove the steering remote control after loosening the screws.

Categories

- Manuals Home

- Hyundai Ioniq Owners Manual

- Hyundai Ioniq Service Manual

- Body (Interior and Exterior)

- Engine Mechanical System

- Hybrid Control System

- New on site

- Most important about car