Hyundai Ioniq (AE): Hybrid Control System / Specifications

Hybrid Control System

â–· Type : ON/OFF Switch

â–· Specification

Item

|

Brake PedalRelease

|

Brake PedalPush

|

Switch 1

| Max. 0.5V

| Battery Voltage

|

Switch 2

| IG OFF

| Max. 50 mV

|

IG ON

| Battery Voltage

| Max. 0.5V

|

Items

|

Specification

|

Gap [mm (in)]

| 1.0 - 2.0 (0.039 - 0.079)

|

â–· Specification

Item

|

Specification

|

Rated Current (A)

| 30

|

High Voltage Battery System

â–· Type : LiPB (Lithium ion Polymer Battery), Pouch type

â–· Specification

[General Specification]

Item

|

Specification

|

Remarks

|

Number of Cells

| 16 Cells x 4 Modules

| 1 Cells = 3.75V

|

Rated Voltage (V)

| 240

| Terminal voltage at Rated 1C discharge, SOC 55%, 20°C (68°F)

|

Nominal Capacity (Ah)

| 6.5

| [Beginning of life, 20°C (68°F)]

|

Rated Energy (Wh)

| 1,560

| Rated Voltage x Nominal Capacity

|

[Operational Specification]

Item

|

Specification

|

Discharge Power (kW)

| Max. 42

|

Charge Power (kW)

| Max. 39

|

Operation Voltage (V)

| 160 - 275

[2.5V ≤ Cell Voltage ≤ 4.3V]

|

Operation Current (A)

| -250 - 250

|

| Power Relay Assembly (PRA) |

â–· Specification

Item

|

Specification

|

Rated Voltage (V)

| 450

|

Rated Current (A)

| 80

|

High Voltage Battery Control System

â–· Specification

Item

|

Specification

|

Rated Voltage (V)

| 400

|

Rated Current (A)

| 80

|

Fuse Rated Current (A)

| 125

|

Fuse Melting Time

| Rated Current x 110%

| Min. 4 hr

|

Rated Current x 200%

| 5 - 100 sec

|

Rated Current x 300%

| 0.5 - 15 sec

|

Rated Current x 500%

| Max. 1 sec

|

â–· Specification

Item

|

Specification

|

Contact

| Rated Voltage (V)

| 450

|

Rated Current (A)

| 80

|

Coil

| Operating Voltage (V)

| 12

|

Resistance (Ω)

| 20.0 - 40.0

[20°C (68°F)]

|

â–· Specification

Item

|

Specification

|

Contact

| Rated Voltage (V)

| 450

|

Rated Current (A)

| 20

|

Coil

| Operating Voltage (V)

| 12

|

Resistance (Ω)

| 40.0 - 110.0

[20°C (68°F)]

|

â–· Specification

Item

|

Specification

|

Resistance (Ω)

| 40 [20°C (68°F)]

|

Rated Current (A)

| 40

|

â–· Specification

Current (A)

|

Output Voltage (V)

|

-300 (Charge)

| 0.5

|

0

| 2.5

|

+300 (Discharge)

| 4.5

|

| Battery Temperature Sensor (HEV) |

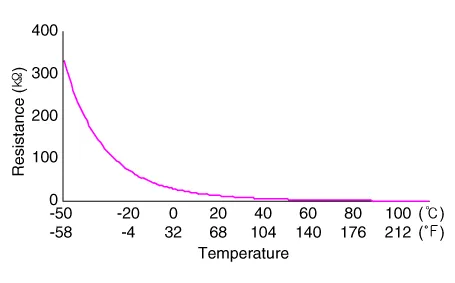

â–· Type : Thermisor type

â–· Specification

[Air Inlet]

Temperature

|

Resistance (kΩ)

|

°C

|

°F

|

-50

| -58

| 314.9 - 344.6

|

-40

| -40

| 181.1 - 196.0

|

-30

| -22

| 107.5 - 115.2

|

-20

| -4

| 65.82 - 69.77

|

-10

| 14

| 41.43 - 43.52

|

0

| 32

| 26.74 - 27.83

|

10

| 50

| 17.67 - 18.25

|

20

| 68

| 11.94 - 12.24

|

30

| 86

| 8.214 - 8.411

|

40

| 104

| 5.738 - 5.918

|

50

| 122

| 4.082 - 4.239

|

60

| 140

| 2.954 - 3.087

|

70

| 158

| 2.172 - 2.284

|

80

| 176

| 1.621 - 1.715

|

90

| 194

| 1.227 - 1.305

|

100

| 212

| 0.941 - 1.006

|

110

| 230

| 0.731 - 0.785

|

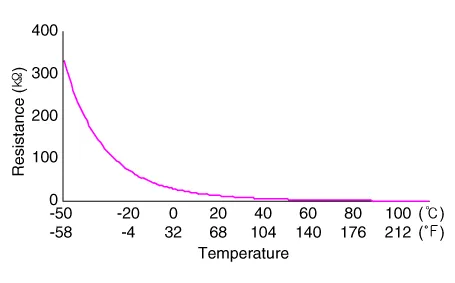

[Cell]

Temperature

|

Resistance (kΩ)

|

°C

|

°F

|

-50

| -58

| 351.1 - 385.0

|

-40

| -40

| 196.6 - 213.1

|

-30

| -22

| 114.4 - 122.7

|

-20

| -4

| 68.94 - 73.15

|

-10

| 14

| 42.59 - 44.76

|

0

| 32

| 27.14 - 28.27

|

10

| 50

| 17.78 - 18.36

|

20

| 68

| 11.96 - 12.25

|

30

| 86

| 8.202 - 8.399

|

40

| 104

| 5.721 - 5.901

|

50

| 122

| 4.069 - 4.226

|

60

| 140

| 2.945 - 3.078

|

70

| 158

| 2.169 - 2.280

|

80

| 176

| 1.622 - 1.715

|

90

| 194

| 1.228 - 1.306

|

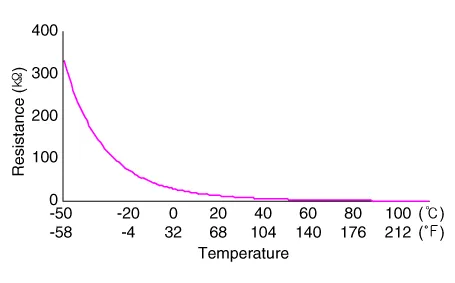

| Auxiliary Battery Temperature Sensor |

â–· Type : Thermisor type

â–· Specification

Temperature

|

Resistance (kΩ)

|

°C

|

°F

|

-20

| -4

| 251.7 - 291.9

|

0

| 32

| 90.1 - 100.2

|

25

| 77

| 29.10 - 30.90

|

50

| 122

| 10.41 - 11.51

|

80

| 176

| 3.56 - 4.11

|

High Voltage Battery Cooling System

â–· Specification

Duty (%)

|

Fan Speed (rpm)

|

10

| 500

|

20

| 1000

|

30

| 1300

|

40

| 1600

|

50

| 1900

|

60

| 2200

|

70

| 2500

|

80

| 2800

|

90 (Max.)

| 3100

|

95 (Max.)

| 3850

|

| Low Voltage DC/DC Converter (LDC) |

â–· Specification

Item

|

Specification

|

Input Voltage (V)

| 200 - 310

|

Output Voltage (V)

| 12.8 - 14.7

|

Rated Power (kW)

| 1.8

|

Cooling Method

| Water-cooled

|

Hybrid Control System

Item

|

kgf.m

|

N.m

|

lb-ft

|

HPCU installation bolt

| 2.0 - 3.0

| 19.6 - 29.4

| 14.5 - 21.7

|

High Voltage Battery System

Item

|

kgf.m

|

N.m

|

lb-ft

|

High voltage battery pack assembly installation bolt

| 8.0 - 12.0

| 78.5 - 117.7

| 57.9 - 86.8

|

High voltage battery front cover installation bolt / nut

| 0.8 - 1.2

| 7.8 - 11.8

| 5.8 - 8.7

|

High voltage battery rear cover installation bolt

| 0.8 - 1.2

| 7.8 - 11.8

| 5.8 - 8.7

|

High voltage power cable terminal tightening nut

| 0.8 - 1.2

| 7.8 - 11.8

| 5.8 - 8.7

|

Power relay assembly installation nut

| 0.8 - 1.2

| 7.8 - 11.8

| 5.8 - 8.7

|

High Voltage Battery Control System

Item

|

kgf.m

|

N.m

|

lb-ft

|

BMS ECU installation nut

| 0.8 - 1.2

| 7.8 - 11.8

| 5.8 - 8.7

|

High Voltage Battery Cooling System

Item

|

kgf.m

|

N.m

|

lb-ft

|

Cooling fan installation nut

| 0.8 - 1.2

| 7.8 - 11.8

| 5.8 - 8.7

|

Cooling fan bracket installation nut

| 0.8 - 1.2

| 7.8 - 11.8

| 5.8 - 8.7

|

Inlet cooling duct installation nut

| 0.8 - 1.2

| 7.8 - 11.8

| 5.8 - 8.7

|

Outlet cooling duct installation nut

| 0.8 - 1.2

| 7.8 - 11.8

| 5.8 - 8.7

|

Low Voltage DC/DC Converter (LDC)

Item

|

kgf.m

|

N.m

|

lb-ft

|

LDC ground tightening bolt

| 1.1 - 1.4

| 10.8 - 13.7

| 7.9 - 10.1

|

LDC power outlet cable tightening bolt

| 1.1 - 1.4

| 10.8 - 13.7

| 7.9 - 10.1

|

Hybrid Electric Vehicle (HEV)The Hybrid Electric Vehicle (HEV) uses hybrid power source (Engine, Electric motor), so its fuel efficiency is relatively high and exhaust emission is very small compared to the traditional vehicle which uses only engine as power source.

Personal Protective Equipment

Name

Illustration

Description

Insulation gloveUsed when inspecting or working on the high voltage components[Insulation performance : 1000V / 300A or above]Insulation shoesUsed when inspecting or working on the high voltage componentsInsulation clothesInsulation helmetSafety glassesUsed in the case below • During Removal & installation or inspection of the high voltage battery terminals or wiring, which spark might happen.

Other information:

DescriptionThe A/C Pressure Transducer (APT) converts the pressure value of high pressure line into voltage value after measuring it. By converted voltage value, engine ECU controls the cooling fan by operating it high speed or low speed. Engine ECU stops the operation of the compressor when the temperature of refrigerant line is very high or very

S