Hyundai Ioniq (AE): Front View Camera System / Description and operation

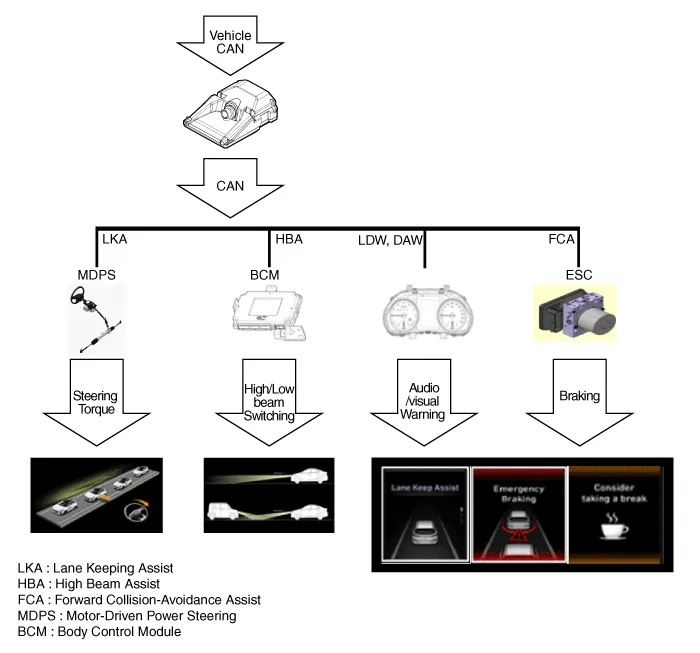

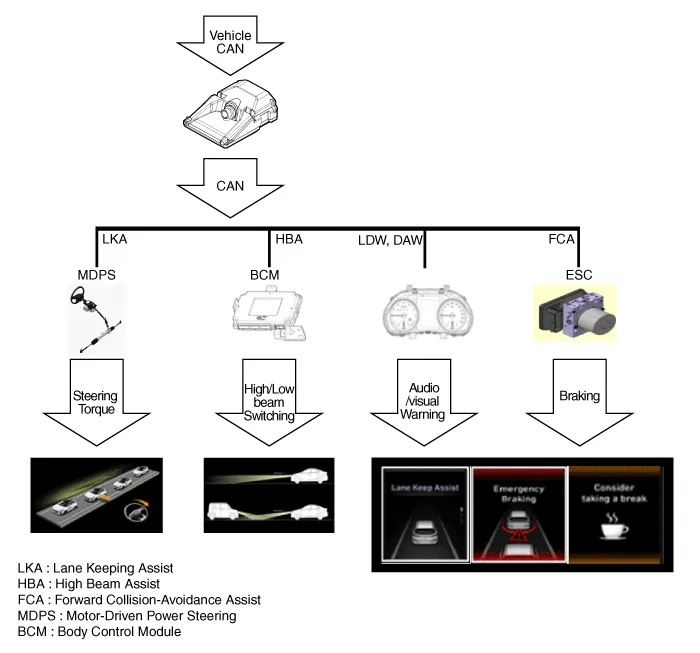

Blcok Diagram

| Functions of Front View Camera |

Front View Camera supports the following functions using the information (lane, light source, vehicle and pedestrian) detected by the front view camera and the vehicle's signal information (CAN communication).

| 1. | Lane Keeping Assist (LKA) : If it is judged that the vehicle leaves the road during driving, the driver is warned of the danger and the steering is controlled in order to prevent the accident. The LKA provides visual / audible warning to the driver if it is determined that the lane departs from the lane in consideration of the lane and road boundary information recognized by the front view camera and whether or not the turn signal lamp operates. However, the front view camera may not operate normally in the limit situation where the lane and road boundaries can not be recognized. |

| 2. | High Beam Assist (HBA) : High Beam Assist (HBA) controls the operation of the high beam in order to maximize the front visual range while minimizing casting the glare on other drivers at night and under low light conditions. The system uses the front camera to detect whether there is any light source from the front or oncoming vehicle or street light. The system turns off the high beam if there is a light source and turns on the high beam if there is no light source. However, when the front view camera is unable to detect the surrounding situation, the system may not operate normally. |

| 3. | Forward Collision-Avoidance Assist(FCA) : It warns the driver of risk and controls the braking of the vehicle to prevent collision with front obstacle during driving. (If Sensor Fusion FCA is equipped) THE MFC transmits the recognition information about the forward vehicle/pedestrain to the front radar using CAN communication for FCA operation. |

| 4. | Driver Attention Warning(DAW) : If it is judged that the driver is inattention driving, the driver is warned to prevent an accident. The DAW analyzes the driving patttern of the driver in consideration of the lane information recognized by the front camera and the information such as the speed/steering angle/brake operation of the vehicle, and gives a visual/audible warning to the driver when it is determined that the driver is inadvertent driving. However, the front camera may not operate normally in a marginal situation where the surroundings can not be recognized. |

The functional requirements of MFC are as follows:

| 1. | Lane Keeping Assist (LKA) | ŌĆō

| It operates when the LKA function is set and the vehicle speed is over 40mph(60km/h). (LKA Function Setting : LKA Switch ON, USM LKA Mode) |

| ŌĆō

| The lines should be clearly separated, and both lanes should be detected. |

| ŌĆō

| The driver's hand should be placed on the steering wheel and the function is canceled if ignoring the steering force when the LKA function is activated. |

| ŌĆō

| LKA will operate If the lane change is made arbitrarily while the turn signal lamp and emergency light switch are OFF. |

| ŌĆō

| LKA operates at a lane width of 2.8m or more and 4.3m or less. |

| ŌĆō

| If the vehicle crosses more than 40% of the width of the vehicle, it is judged that the lane is deviated to change the lane and the LKA function is canceled. |

| ŌĆō

| In the following cases, the LKA may not operate. |

| 1) | When driving on a steep curve |

| 2) | Sudden braking or sudden change of lane |

| 3) | When the ESC / VSM function is working |

|

| 2. | High Beam Assist (HBA) | 1) | If the light switch is pushed to the instrument panel, the high beam is turned on and the HBA is OFF. |

| 2) | Operates when the vehicle speed is more than 25mph(40km/h). |

| 3) | Details of the operation according to the state of the lighting switch during operation of the High Beam Assist (HBA) system are as follows: |

| ŌĆō

| If the light switch is pushed to the instrument panel, the high beam is turned on and the HBA is OFF. |

| ŌĆō

| If the light switch is pulled up with the high beam being turned off, the high beam is turned on and HBA remains ON. (When you release the hand, the switch moves to the center and the high beam is turned off.) |

| ŌĆō

| When the light switch is turned on with the high beam turned on by the HBA, the high beam is turned off and the system is released. |

| ŌĆō

| If you turn the light switch from AUTO to the headlight position, the high beam is turned off and the system is released. |

| ŌĆō

| During HBA operation with high beam is turned on, the headlamp automatically switches to the high beam off state if: |

| 4) | Detecting the headlights or tail lights of an approaching vehicle |

| ŌĆō

| Detecting the headlights or tail lights of an approaching vehicle |

| ŌĆō

| Detecting the headlights or tail lights of bicycles and motorcycles |

| ŌĆō

| The surroundings are bright enough not to turn on the headlights |

| ŌĆō

| There is a street light or other light in front |

| ŌĆō

| The light switch is not in the AUTO (auto light) position |

| ŌĆō

| The HBA is turned off |

| ŌĆō

| The vehicle speed is reduced to 15mph(24km/h) or less |

| 5) | Even if the HBA operating condition is satisfied, it does not work in the daytime. |

| 6) | Recognizes the lamp source of the preceding vehicle in normal nighttime environment and automatically high beam turns on or off. |

|

Components1. LKA ON/OFF Switch2. Instrument Cluster3. Front View Camera

Service Point Target Auto Calibration (SPTAC)When you need calibration :ŌĆō

Front view camera is removed and mountedŌĆō

Replace front view camera with a new one ŌĆō

Windshield glass changedŌĆō

Front view camera coupler of the windshield glass is deformedService Point Target Auto Calibration (SPTAC)Front view camera SPTAC provides the method for the service technician to calibrate the camera by aligning the calibration target (SST: 09890-3V100) with the vehicle on a level ground.

Other information:

C

Replacement1.Disconnect the negative (-) battery terminal. 2.Remove the heater and blower assembly.(Refer to Heater - "Heater Unit") 3.Remove the evaporator core cover (A) after loosening the mounting screws.4.Pull out the evaporator temperature sensor (A) from the evaporator core.