Hyundai Ioniq (AE): AHB(Active Hydraulic Boost) System / Hydraulic Power Unit. Repair procedures

Hyundai Ioniq (AE) 2017-2022 Service & Repair Manual / Brake System / AHB(Active Hydraulic Boost) System / Hydraulic Power Unit. Repair procedures

| Removal |

| 1. | Turn ignition switch OFF and disconnect the negative (-) battery cable. |

| 2. | Remove the wiring bracket.

|

| 3. | Remove the brake fluid from the reservoir with a syringe.

|

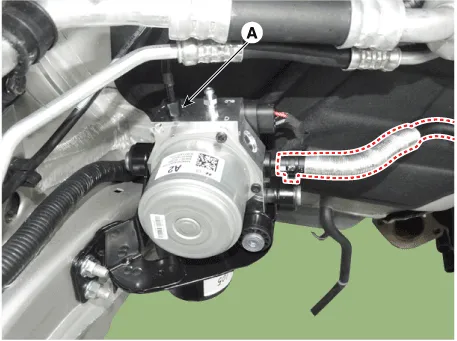

| 4. | Loosening the flare nut (A) and then disconnect the brake tube.

|

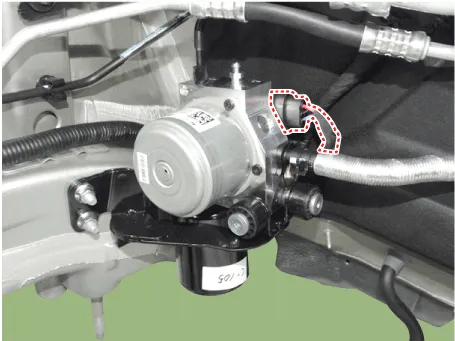

| 5. | Disconnect the PSU connector.

|

| 6. | Remove the front sub frame. (Refer to Suspension System - "Sub Frame") |

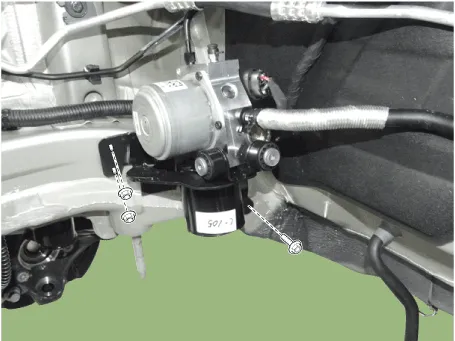

| 7. | Loosen the mounting bolt and nut then remove the PSU.

|

| Installation |

| 1. | Installation is the reverse of removal. |

| 2. | Tighten the PSU bracket bolts and brake tube to the specified torque. |

| 3. | After filling the brake fluid in the reservoir, perform the air bleed. . (Refer to AHB System - "AHB System Air Bleeding") |

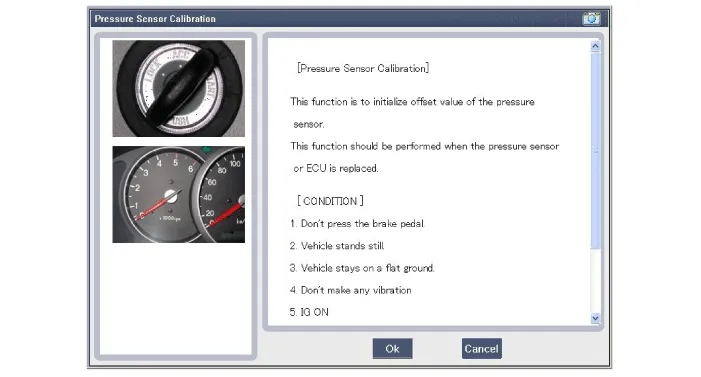

| 4. | Conduct Pressure sensor Calibration. |

| 5. | Check the brake pedal operation. |

| Diagnostic Procedure Using GDS |

The following section describes how to diagnose faults using a diagnostic instrument.

| 1. | Connect the diagnostic instrument to the self-diagnostic connector (16-pin) beneath the crash pad on the side of driver's seat, and then turn on the ignition to activate the diagnostic instrument. |

| 2. | In the GDS Vehicle Type Selection menu, select "Vehicle Type" and "ABS/ESC" System, and then opt for "OK." [Pressure Sensor Calibration]

|

| 3. | Turn ignition switch off and on after calibration procedure. |

| 4. | Confirm success of calibration. |

Components • PSU (Presser Source Unit) must not be disassembled.1. Pressure Source Unit (PSU)2. Pressure Source Unit (PSU) connector3.

Categories

- Manuals Home

- Hyundai Ioniq Owners Manual

- Hyundai Ioniq Service Manual

- Jump starting procedure

- General Information

- Brake Fluid

- New on site

- Most important about car

Copyright © 2026 www.hioniqae.com - 0.0503