Hyundai Ioniq (AE): Brake System / Rear Disc Brake. Repair procedures

| Removal |

| 1. | Loosen the wheel nuts slightly. Raise the vehicle, and make sure it is securely supported. |

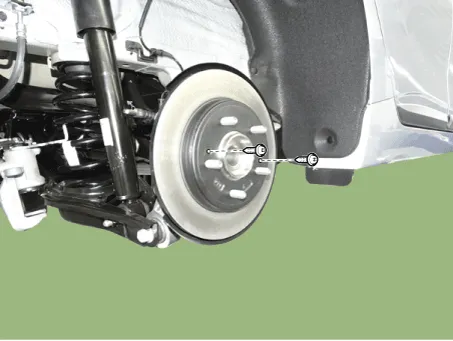

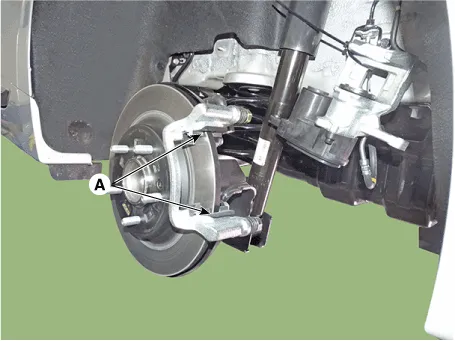

| 2. | Remove the rear wheel and tire (A) from the rear hub.

|

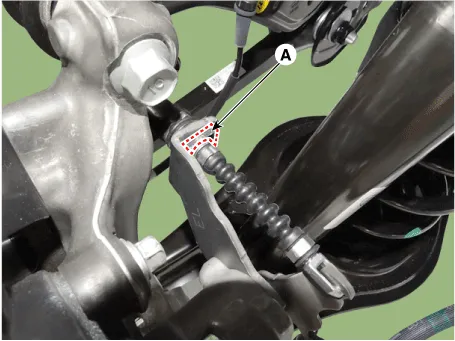

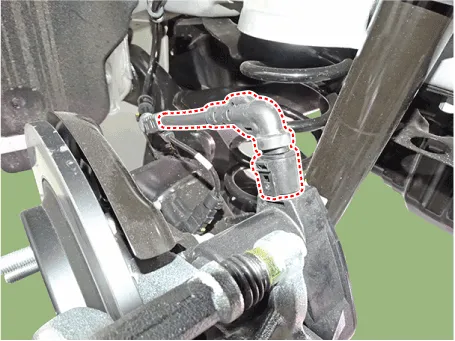

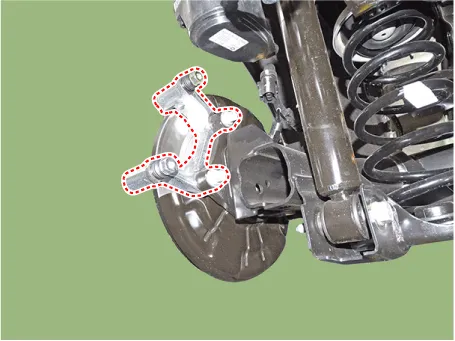

| 3. | Remove the parking brake cable fixed clip (A).

|

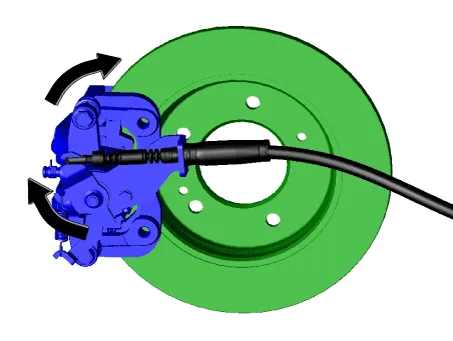

| 4. | Pull the operating lever as a direction of arrow in the illustration below and then remove the parking brake cable.

|

| 5. | Loosen the guide rod bolt and then pivot the caliper body up out of the way.

|

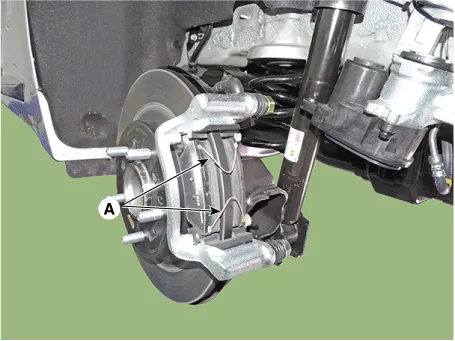

| 6. | Remove the pad return spring (A).

|

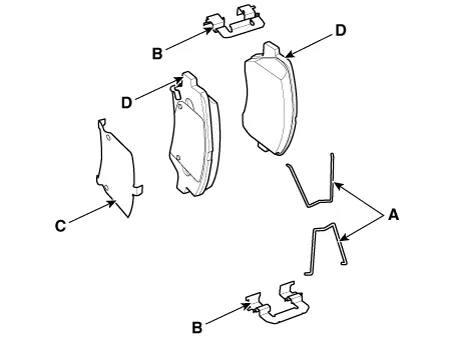

| 7. | Separate the brake pad and pad retainer.

|

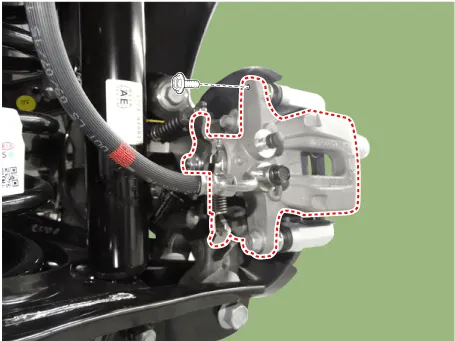

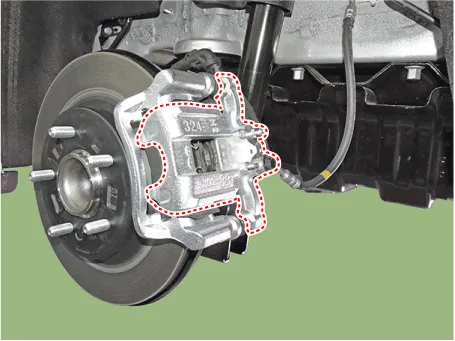

| 8. | Loosen the caliper mounting bolts and then removethe rear caliper assembly (A).

|

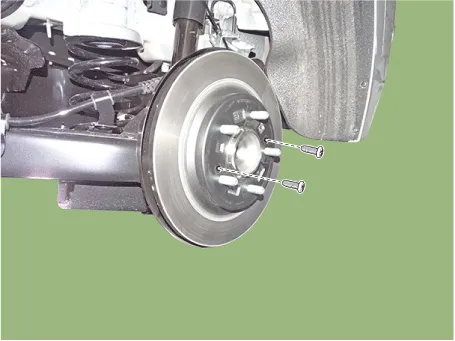

| 9. | Remove the rear brake disc by loosening the screws.

|

| 1. | Loosen the wheel nuts slightly. Raise the vehicle, and make sure it is securely supported. |

| 2. | Remove the rear wheel and tire (A) from the rear hub.

|

| 3. | Disconnect the EPB connector.

|

| 4. | Loosen the guide rod bolt and then remove the caliper body.

|

| 5. | Remove the pad return spring (A).

|

| 6. | Remove the brake pad.

|

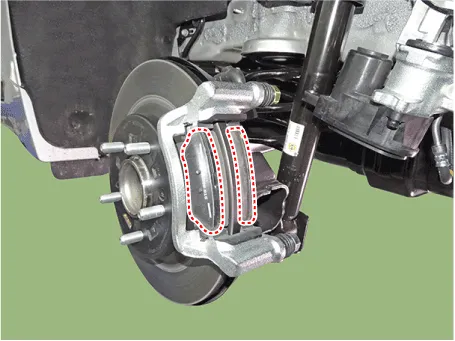

| 7. | Remove the pad retainer (A).

|

| 8. | Loosen the caliper mounting bolts and then removethe rear caliper assembly (A).

|

| 9. | Remove the rear brake disc by loosening the screws.

|

| Replacement |

| [EPB None Apply] |

| 1. | Loosen the wheel nuts slightly. Raise the vehicle, and make sure it is securely supported. |

| 2. | Remove the rear wheel and tire (A) from the rear hub.

|

| 3. | Remove the parking brake cable fixed clip (A).

|

| 4. | Pull the operating lever as a direction of arrow in the illustration below and then remove the parking brake cable.

|

| 5. | Loosen the guide rod bolt and then pivot the caliper body up out of the way.

|

| 6. | Remove the pad return spring (A).

|

| 7. | Replace the brake pad and pad retainer.

|

| 8. | Install the pad return spring (A).

|

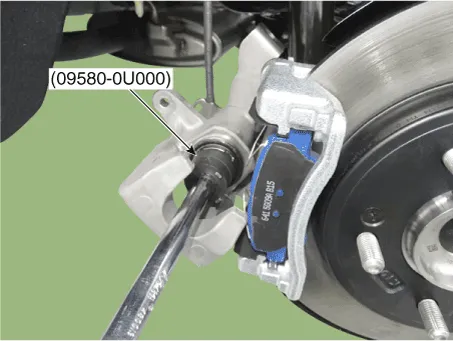

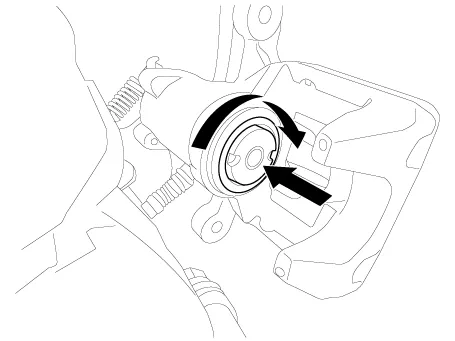

| 9. | Use a SST (09580-0U000) when installing the brake caliper assembly.

|

| 10. | Install the caliper body (A) then tighten the guide rod bolt (B).

|

| 11. | Pull the operating lever as a direction of arrow in the illustration below and then install the parking brake cable.

|

| 12. | Install the parking brake cable fixed clip (A).

|

| 13. | Install the rear wheel and tire (A) from the rear hub.

|

| [EPB Apply] |

| 1. | Loosen the wheel nuts slightly. Raise the vehicle, and make sure it is securely supported. |

| 2. | Remove the rear wheel and tire (A) from the rear hub.

|

| 3. | Disconnect the EPB connector.

|

| 4. | Loosen the guide rod bolt and then remove the caliper body.

|

| 5. | Remove the pad return spring (A).

|

| 6. | Remove the brake pad.

|

| 7. | Remove the pad retainer (A).

|

| 8. | Install the pad return spring (A).

|

| 9. | Install the caliper body (A) then tighten the guide rod bolt (B).

|

| 10. | Connect the EPB connector.

|

| 11. | Install the rear wheel and tire (A) from the rear hub.

|

| Inspection |

| 1. | Check the brake pads for wear and fade. |

| 2. | Check the brake disc for damage and cracks. |

| 3. | Remove all rust and contamination from the surface, and measure the disc thickness at 24 points, at least, of same distance (5mm) from the brake disc outer circle.

|

| 4. | If wear exceeds the limit, replace the discs and pad assembly left and right of the vehicle. |

| 1. | Check the pad wear. Measure the pad thickness and replace it, if it is less than the specified value.

|

| 2. | Check the damage of pad, backing metal and contamination with grease. |

| 1. | Place a dial gauge about 10mm (0.2 in.) from the outer circumference of the brake disc, and measure the runout of the disc.

|

| 2. | If the runout of the brake disc exceeds the limit specification, replace the disc, and then measure the runout again. |

| 3. | If the runout exceeds the limit specification, install the brake disc after turning it 180° and then check the runout of the brake disc again. |

| 4. | If the runout cannot be corrected by changing the position of the brake disc, replace the brake disc. |

| Installation |

| 1. | To install, reverse the removal procedure. |

| 2. | Use a SST (09580-0U000) when installing the brake caliper assembly.

|

| 3. | After installing, bleed the brake system. (Refer to Brake System - "Brake System Bleeding") |

| Adjustment |

|

| 1. | Remove the floor console to reach the adjusting nut. |

| 2. | Loosen the parking brake cable until both operating levers rest in fully off position. |

| 3. | Bring the brake pads in their operating position by pressing the brake pedal down several times until there is resistance. |

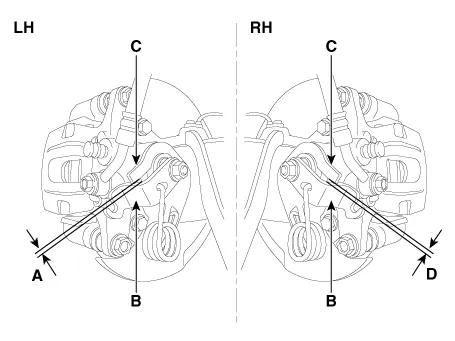

| 4. | Tension the parking brake cable by tightening the adjusting nut, until the operating levers on both calipers lift from the stop, up to a distance of (A) and (D) between operating lever (B) and stopper (C).

|

| 5. | Refit the floor console. |

| 6. | Parking brake lever in the car must be in fully loosened position. |

| 7. | If the handbrake cables where changed, actuate the parking brake a few times with maximum force to stretch the parking brake cables, and then control adjusting as above. |

| 8. | Check the wheels of their free operation. |

| 9. | Test drive. |

Components[EPB None Apply]1. Brake pad2. Pad return spring3. Caliper carrier4. Pad retainer5. Caliper body6. Bleed screw7. Stopper8. Return spring9. Operating lever[EPB Apply]1.

Components Location1. Brake pedal member assembly2. Stop lamp switch3. Brake pedal arm assembly4. Brake pedal pad5. Pedal stroke sensor

Other information:

Hyundai Ioniq (AE) 2017-2022 Service & Repair Manual: Ambient Temperature Sensor. Repair procedures

Inspection1.Check the resistance of the ambient temperature sensor between terminals 1 and 2 whether it changes by changing the ambient temperature.1. Ambient Sensor (+)2. Sensor groundSpecification Ambient temperature [°C (°F)] Resistance between terminal 1 and 2 (

Hyundai Ioniq (AE) 2017-2022 Service & Repair Manual: Repair procedures

Removal1.Disconnect the negative (-) battery terminal.2.Remove the tailgate lid trim.(Refer to Body - "TailGate Lid Trim")3.Disconnect the Rear view camera connector (A).4.Remove the Rear view camera assembly after loosening the mounting screws.Installation1.

Categories

- Manuals Home

- Hyundai Ioniq Owners Manual

- Hyundai Ioniq Service Manual

- Hybrid Control System

- Maintenance

- Engine Mounting. Components and components location

- New on site

- Most important about car