Hyundai Ioniq (AE): Gear Actuator Assembly / Repair procedures

| Removal |

|

|

|

| 1. | Shut off the High Voltage circuit. (Refer to General Information - "High Voltage Shutoff Procedure") |

| 2. | Remove the engine room under cover. (Refer to Engine And Transaxle Assembly - "Engine Room Under Cover") |

| 3. | Loosen the drain plug, and drain the inverter coolant. Remove the reservoir cap to help drain the coolant faster. (Refer to Hybrid Motor System - "Coolant") |

| 4. | Remove the HPCU (Hybrid Power Control Unit). (Refer to Hybrid Control System - "Hybrid Power Control Unit (HPCU)") |

| 5. | Remove the ECM (Engine Control Module) and TCM (Transmssion Control Module). (Refer to Engine Control/Fuel System - "Engine Control Module (ECM)") (Refer to Dual Clutch Control System - "DCT Control Module (TCM)") |

| 6. | Remove the HPCU (Hybrid Power Control Unit) tray. (Refer to Hybrid Control System - "Hybrid Power Control Unit (HPCU)") |

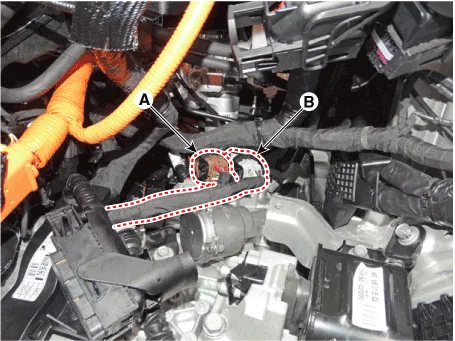

| 7. | Disconnect the gear actuator motor connector (A) and solenoid connector (B).

|

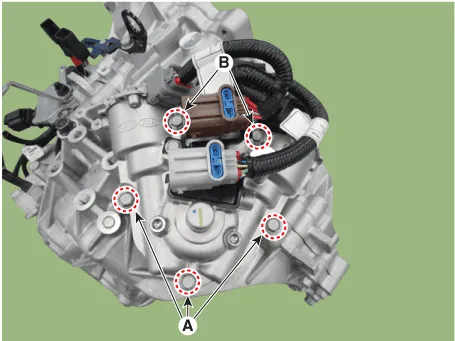

| 8. | Remove the gear actuator assembly after loosening bolts (A-3ea, B-2ea).

|

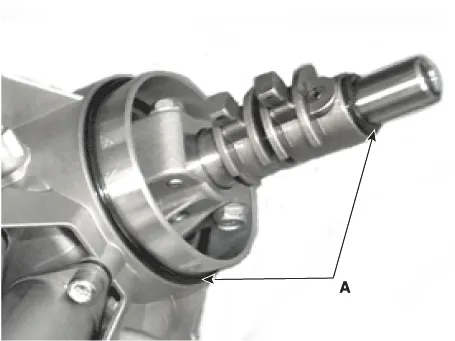

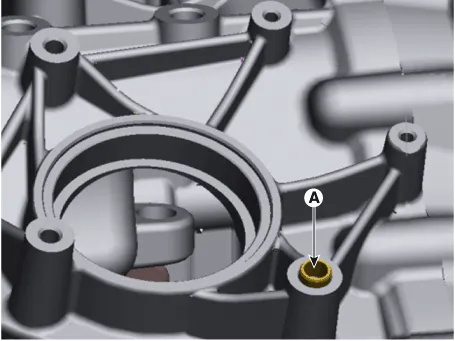

| Installation |

| 1. | Install in the reverse order of removal.

|

Circuit Diagram

Other information:

Hyundai Ioniq (AE) 2017-2022 Service & Repair Manual: Auto Defogging Sensor. Description and operation

DescriptionThe auto defogging sensor is installed on the front window glass. The sensor judges and sends signal if moisture occurs to blow out wind for defogging. The air conditioner control module receives signal from the sensor and restrains moisture and eliminate defog by controlling the intake actuator, A/C, auto defogging actuator, blower moto

Hyundai Ioniq (AE) 2017-2022 Service & Repair Manual: General safety information and caution

General Safety Information and CautionBe careful of the following precautions when driving the vehicle using the smart cruise control system. • The smart cruise control system may have limits in detecting distance to the vehicle ahead due to road and traffic conditions.

Categories

- Manuals Home

- Hyundai Ioniq Owners Manual

- Hyundai Ioniq Service Manual

- Washer Fluid

- If the 12 Volt Battery is Discharged (Hybrid Vehicle)

- Normal Maintenance Schedule

- New on site

- Most important about car

Copyright © 2026 www.hioniqae.com - 0.0206