Hyundai Ioniq (AE): Cylinder Head Assembly / CVVT & Camshaft. Repair procedures

Hyundai Ioniq (AE) 2017-2022 Service & Repair Manual / Engine Mechanical System / Cylinder Head Assembly / CVVT & Camshaft. Repair procedures

| Removal |

|

|

|

| 1. | Shut off the High Voltage circuit. (Refer to General Information - "High Voltage Shutoff Procedure") |

| 2. | Disconnect the battery negative terminal. |

| 3. | Remove the cylinder head cover. (Refer to Cylinder Head Assembly - "Cylinder Head Cover") |

| 4. | Turn the crankshaft damper pulley and align its groove with the timing mark of the timing chain cover to set the piston of No.1 cylinder to the top dead center on compression stroke. |

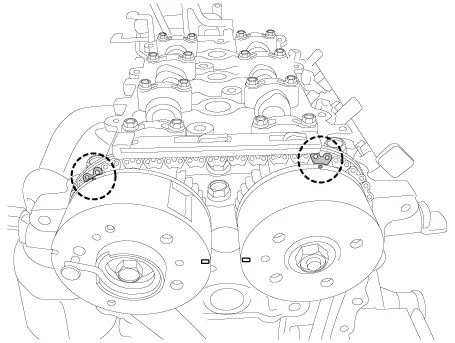

| 5. | Set No.1 cylinder to TDC (Top dead center) on compression stroke.

|

| 6. | Remove the timing chain cover. (Refer to Timing System - "Timing Chain Cover") |

| 7. | Remove the timing chain. (Refer to Timing System - "Timing Chain") |

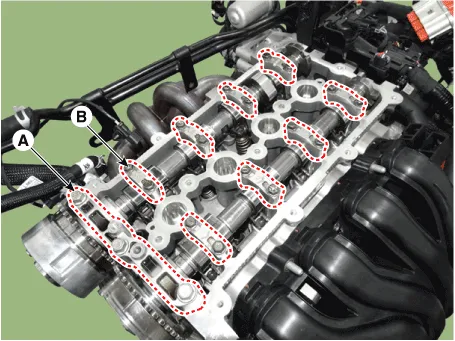

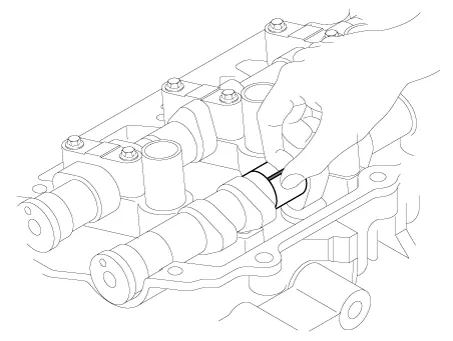

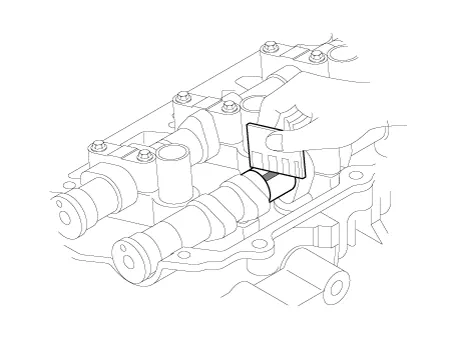

| 8. | Remove the front camshaft bearing cap (A) and the camshaft bearing caps (B).

|

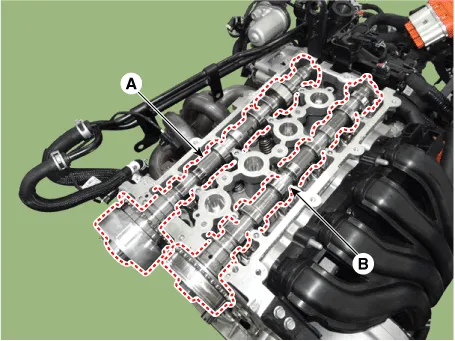

| 9. | Remove the exhaust camshaft (A) first, then intake camshaft (B).

|

| Inspection |

Camshaft

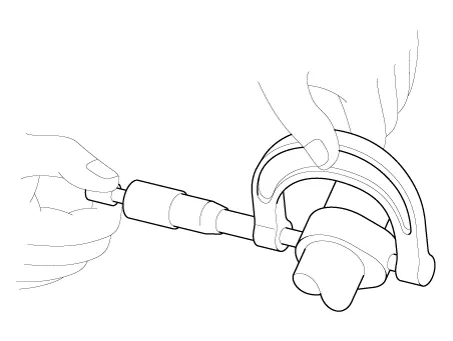

| 1. | Inspect cam lobes. Using a micrometer, measure the cam lobe height.

If the cam lobe height is less than standard, replace the camshaft. |

| 2. | Check the surface of the camshaft journal for wear. If the journal is worn excessively, replace the camshaft. |

| 3. | Inspect the camshaft journal clearance.

|

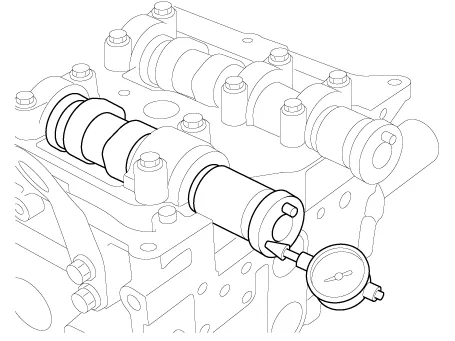

| 4. | Inspect the camshaft end play.

|

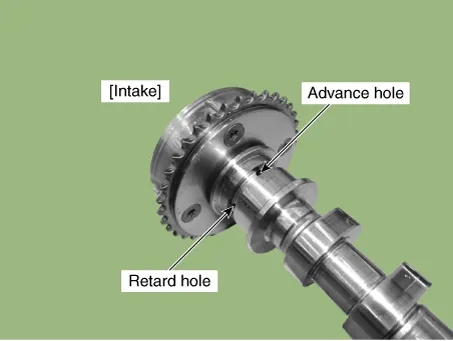

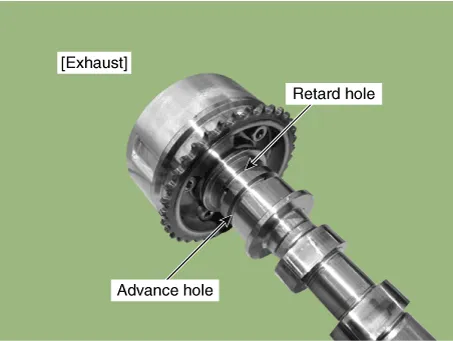

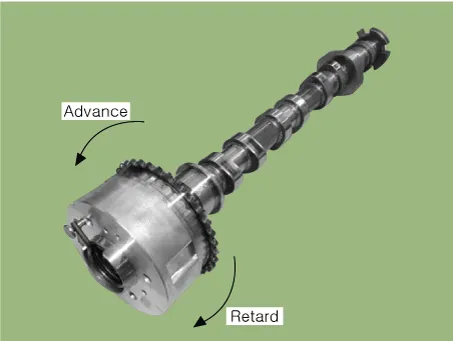

Continuously variable valve timing (CVVT) Assembly

| 1. | Inspect CVVT for smooth rotation.

|

| Installation |

| 1. | Install the exhaust camshaft (A) first, then intake camshaft (B).

|

| 2. | Install the front camshaft bearing cap (A) and the camshaft bearing caps (B) as following method with specified torque.

|

| 3. | Install the timing chain. (Refer to Timing System - "Timing Chain") |

| 4. | Install the timing chain cover. (Refer to Timing System - "Timing Chain Cover") |

| 5. | Install the cylinder head cover. (Refer to Cylinder Head Assembly - "Cylinder Head Cover") |

| 6. | Connect the High Voltage circuit. (Refer to General Information - "High Voltage Shutoff Procedure") |

DescriptionThe continuous variable valve timing (CVVT) system advances or retards the opening of an intake or exhaust valve according to the ECM signals that are determined based on engine RPM and load.

Components1. Cylinder head assembly2. Cylinder head gasket3. Retainer lock4. Retainer5. Valve spring6. Valve stem seal7. Valve8. Swing arm9. Hydraulic lash adjuster (HLA)

Other information:

Hyundai Ioniq (AE) 2017-2022 Service & Repair Manual: A/C Pressure Transducer. Description and operation

DescriptionThe A/C Pressure Transducer (APT) converts the pressure value of high pressure line into voltage value after measuring it. By converted voltage value, engine ECU controls the cooling fan by operating it high speed or low speed. Engine ECU stops the operation of the compressor when the temperature of refrigerant line is very high or very

Hyundai Ioniq (AE) 2017-2022 Service & Repair Manual: Components and components location

C

Categories

- Manuals Home

- Hyundai Ioniq Owners Manual

- Hyundai Ioniq Service Manual

- Engine Mounting. Components and components location

- Engine Control/Fuel System

- Washer Fluid

- New on site

- Most important about car

Copyright ┬® 2026 www.hioniqae.com - 0.0123