Hyundai Ioniq (AE): Engine and Transaxle Assembly / Engine Mounting. Repair procedures

Hyundai Ioniq (AE) 2017-2022 Service & Repair Manual / Engine Mechanical System / Engine and Transaxle Assembly / Engine Mounting. Repair procedures

| Removal and Installation |

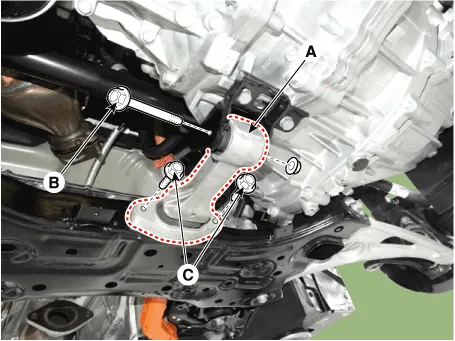

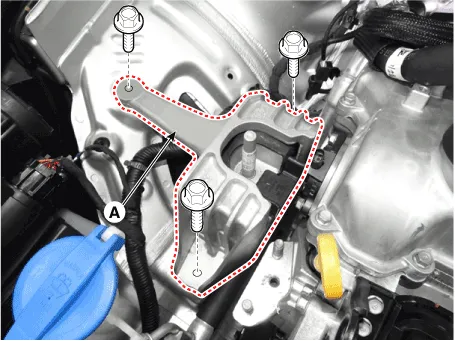

Roll Rod Bracket

| 1. | Remove the roll rod bracket (A).

|

| 2. | Remove the roll rod mounting support bracket (A).

|

| 3. | Install in the reverse order of removal. |

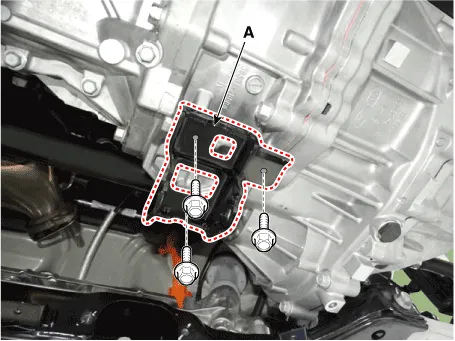

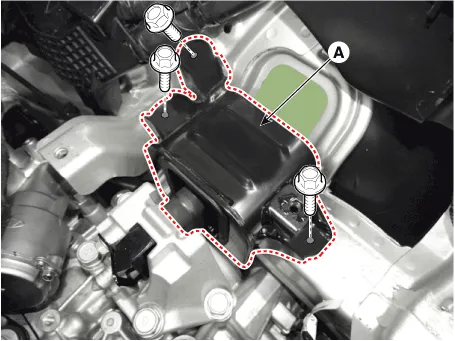

Engine Mounting Bracket

| 1. | Remove the engine room under cover. (Refer to Engine and Transaxle Assembly - "Engine Room Under Cover") |

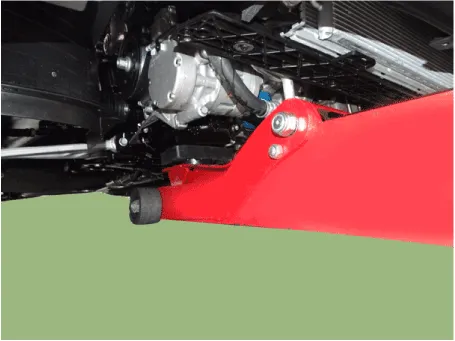

| 2. | Install the jack to the edge of oil pan to support the engine.

|

| 3. | Remove the engine mounting support bracket (A).

|

| 4. | Remove the reservoir tank. (Refer to Cooling System - "Reservoir Tank") |

| 5. | Remove the engine mounting bracket (A).

|

| 6. | Install in the reverse order of removal. |

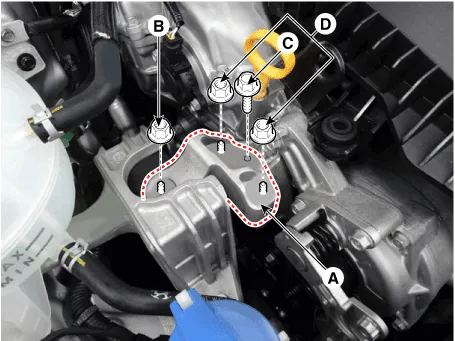

Transaxle Mounting Bracket

|

| 1. | Shut off the High Voltage circuit. (Refer to General Information - "High Voltage Shutoff Procedure") |

| 2. | Disconnect the battery negative terminal. |

| 3. | Remove the engine room under cover. (Refer to Engine and Transaxle Assembly - "Engine Room Under Cover") |

| 4. | Loosen the drain plug, and drain the inverter coolant. Remove the reservoir cap to help drain the coolant faster. (Refer to Hybrid Motor System - "Coolant") |

| 5. | Remove the air cleaner assembly. (Refer to Intake and Exhaust System - "Air Cleaner") |

| 6. | Remove the hybrid power control unit (HPCU). (Refer to Hybrid Control System - "Hybrid Power Control Unit (HPCU)") |

| 7. | Remove the engine control module (ECM) and DCT control module (TCM). (Refer to Engine Control / Fuel System - "Engine Control Module (ECM)") (Refer to Double Clutch Transmission (DCT) System - "DCT Control Module (TCM)") |

| 8. | Remove the hybrid power control unit (HPCU) tray. (Refer to Hybrid Control System - "Hybrid Power Control Unit (HPCU)") |

| 9. | Install the jack under the transaxle to support it. |

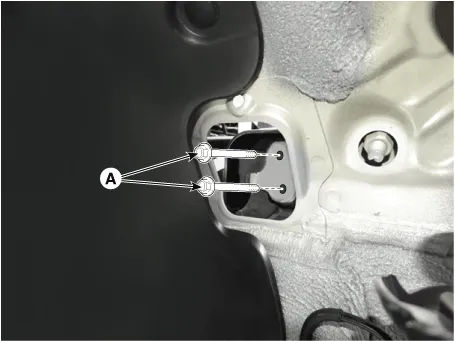

| 10. | Remove the service cover (A).

|

| 11. | Remove the transaxle support bracket mounting bolts (A).

|

| 12. | Remove the transaxle mounting bracket (A).

|

| 13. | Install in the reverse order of removal. |

Components1. Transaxle mounting bracket2. Roll rod bracket3. Engine mounting bracket4. Engine mounting support bracket

Removal • Be sure to read and follow the "General Safety Information and Caution" before doing any work related with the high voltage system.

Other information:

Hyundai Ioniq (AE) 2017-2022 Service & Repair Manual: Ambient Temperature Sensor. Repair procedures

Inspection1.Check the resistance of the ambient temperature sensor between terminals 1 and 2 whether it changes by changing the ambient temperature.1. Ambient Sensor (+)2. Sensor groundSpecification Ambient temperature [°C (°F)] Resistance between terminal 1 and 2 (

Hyundai Ioniq (AE) 2017-2022 Service & Repair Manual: Intake Actuator. Components and components location

C

Categories

- Manuals Home

- Hyundai Ioniq Owners Manual

- Hyundai Ioniq Service Manual

- Auto Defogging System

- Engine Mechanical System

- Checking the Coolant Level

- New on site

- Most important about car

Copyright © 2025 www.hioniqae.com - 0.0295