Hyundai Ioniq (AE): Cylinder Block / Crankshaft. Repair procedures

| Disassembly |

|

|

|

| 1. | Remove the engine assembly from the vehicle. (Refer to Engine and Transaxle Assembly - "Engine and Transaxle Assembly") |

| 2. | Remove the transaxle assembly from the engine assembly. (Refer to Double Clutch Transmission (DCT) System - "Double Clutch Transmission (DCT)") |

| 3. | Remove the flywheel. (Refer to Cylinder Block - "Flywheel") |

| 4. | Remove the rear oil seal. (Refer to Cylinder Block - "Rear Oil Seal") |

| 5. | Install the engine to engine stand for disassembly. |

| 6. | Remove the intake manifold. (Refer to Intake and Exhaust System - "Intake Manifold") |

| 7. | Remove the exhaust manifold. (Refer to Intake and Exhaust System - "Exhayst Manifold") |

| 8. | Remove the hybrid starter generator (HSG). (Refer to Hybrid Motor System - "Hybrid Starter Generator (HSG)") |

| 9. | Remove the timing chain. (Refer to Timing System - "Timing Chain") |

| 10. | Remove the cylinder head assembly. (Refer to Cylinder Head Assembly - "Cylinder Head") |

| 11. | Remove the thermostat. (Refer to Cooling System - "Thermostat") |

| 12. | Remove the EGR cooler. (Refer to Intake and Exhaust System - "EGR Cooler") |

| 13. | Remove the A/C compressor. (Refer to Heating, Ventilation Air conditioning -"Compressor") |

| 14. | Remove the knock sensor. (Refer to Engine Control / Fuel System - "Knock Sensor") |

| 15. | Remove the oil pan and oil screen. (Refer to Lubrication System - "Oil Pan") |

| 16. | Remove the ladder frame. (Refer to Cylinder Block - "Piston and Connecting Rod") |

| 17. | Remove the piston and connecting rod assemblies. (Refer to Cylinder Block - "Piston and Connecting Rod") |

| 18. | Remove the main bearing caps and check oil clearance. |

| 19. | Check the crankshaft end play. |

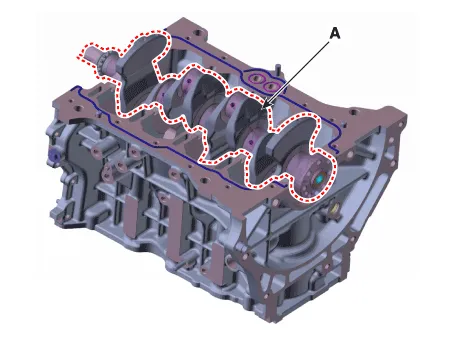

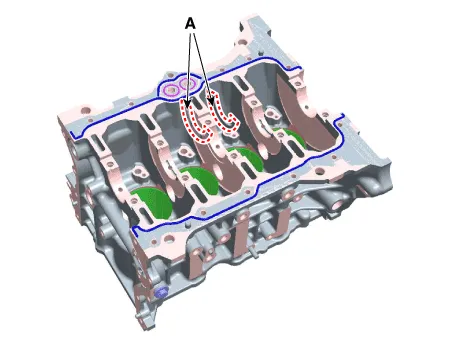

| 20. | Lift the crankshaft (A) out of engine, being careful not to damage journals.

|

| Inspection |

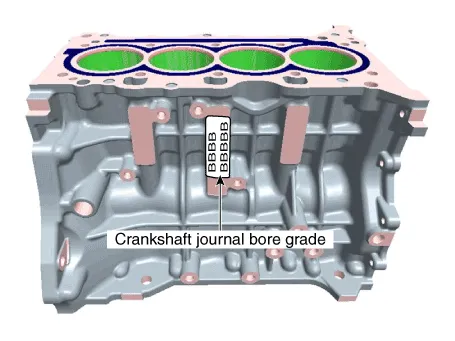

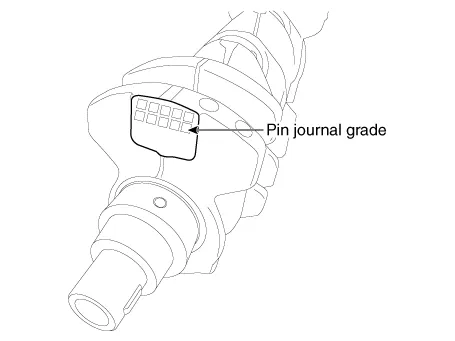

| 1. | Check the crankshaft bearing oil clearance.

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

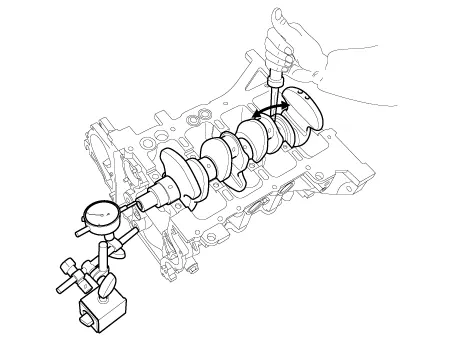

| 2. | Check crankshaft end play. Using a dial indicator, measure the thrust clearance while prying the crankshaft back and forth with a screwdriver.

If the end play is greater than maximum, replace the center bearings as a set. |

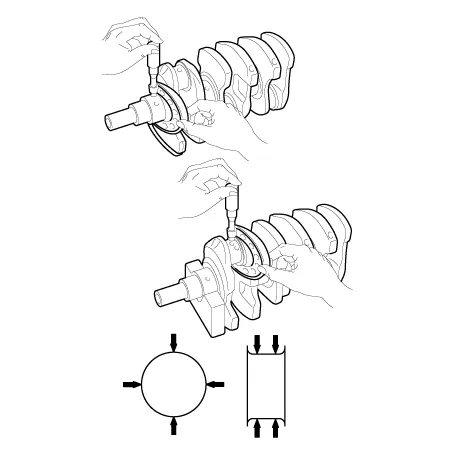

| 3. | Inspect the crankshaft main journals and pin journals. Using a micrometer, measure the diameter of each main journal and pin journal.

|

| Reassembly |

|

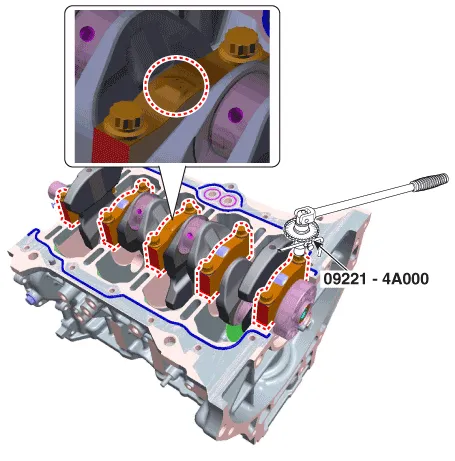

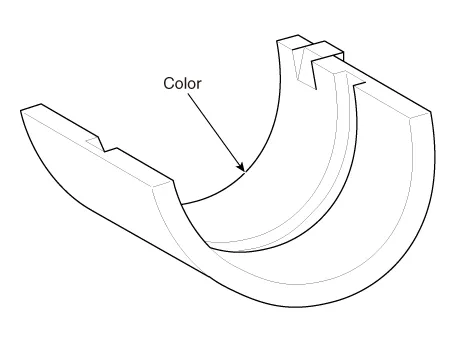

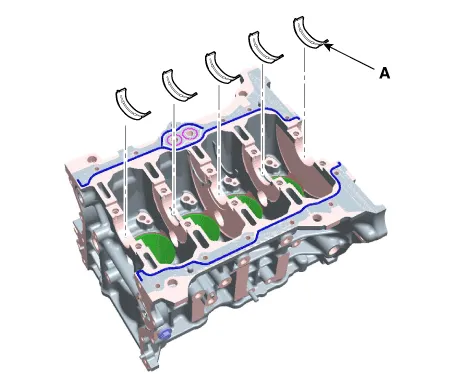

| 1. | Install the crankshaft main bearings.

|

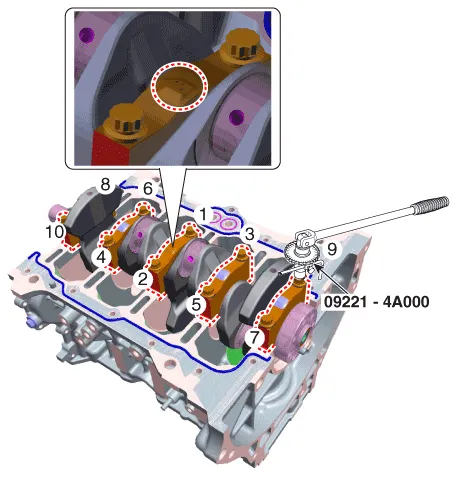

| 2. | Place the crankshaft (A) on the cylinder block.

|

| 3. | Install the main bearing cap (A).

|

| 4. | Check the crankshaft end play. |

| 5. | Assemble the other parts in the reverse order of disassembly. |

Components1. Thrust bearing2. Main bearing (Upper)3. Crankshaft4. Main bearing (Lower)5. Main bearing cap

Disassembly • Be sure to read and follow the "General Safety Information and Caution" before doing any work related with the high voltage system.

Other information:

Hyundai Ioniq (AE) 2017-2022 Service & Repair Manual: Evaporator Temperature Sensor. Repair procedures

Inspection1.Turn the ignition switch OFF.2.Disconnect the evaporator temperature sensor connector.3.Measure the resistance between terminal "+" and "-" of the evaporator temperature sensor.Specification Evaporator core temperature [°C (°F)] Resistance [KΩ]

Hyundai Ioniq (AE) 2017-2022 Service & Repair Manual: Parking Distance Warning (PDW) Sensor. Repair procedures

Removal1.Disconnect the negative (-) battery terminal.2.Remove the front / rear bumper cover.(Refer to Body - "Front Bumper Cover")(Refer to Body - "Rear Bumper Cover")3.Disconnect the connector (A) from the parking assist sensor.4.Remove the sensor (A) by pulling out both ends of the sensor holder.

Categories

- Manuals Home

- Hyundai Ioniq Owners Manual

- Hyundai Ioniq Service Manual

- Jump Starting

- Engine Control/Fuel System

- If the 12 Volt Battery is Discharged (Hybrid Vehicle)

- New on site

- Most important about car